Precision Powerhouse: Nd:YAG Laser Engraving

Welcome to the Precision Powerhouse of Nd:YAG Laser Engraving

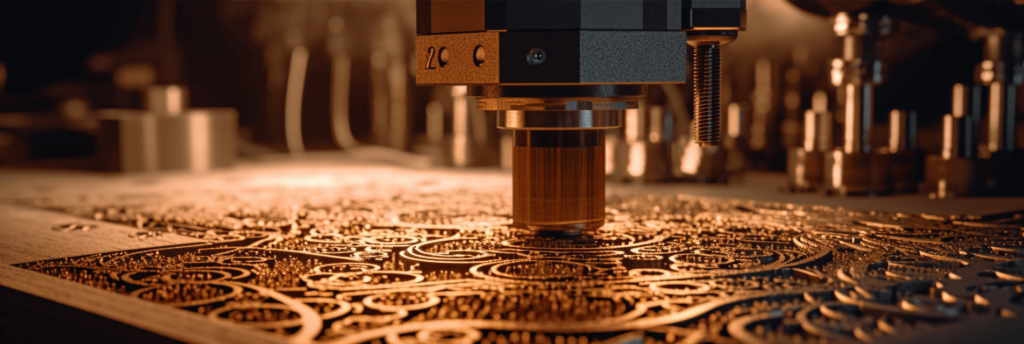

In the world of precision engraving, there’s a cutting-edge technology that stands out above the rest—Nd:YAG laser engraving. This remarkable technique harnesses the power of a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser to achieve unparalleled precision and versatility. Whether you’re in the field of industrial manufacturing, jewelry design, or even healthcare, Nd:YAG laser engraving has the potential to revolutionize your creative process and enhance your productivity.

Laser Engraver WAINLUX K6 Pro, 3000mW Laser Engraving Machine, 0.05mm Accuracy, BT Connection Portable Mini Laser Cutter

The article engraved:

- Unleashing the Potential of Laser Precision

- The Advancements of Nd:YAG Laser Technology

- Understanding Nd:YAG Laser Engraving

- Applications of Nd:YAG Laser Engraving

- Choosing the best Nd:YAG Laser Engraving Machine

- Techniques and Tips for Successful Nd:YAG Laser Engraving

- Innovations and Future Trends in Nd:YAG Laser Engraving

- Nd:YAG Case Studies: Success Stories and Inspirational Examples

- The Impact of Nd:YAG Laser Engraving

- Addressing Common Challenges in Nd:YAG Laser Engraving

- Conclusion

Unleashing the Potential of Laser Precision

When it comes to engraving intricate designs or achieving razor-sharp details, traditional methods often fall short. That’s where Nd:YAG laser engraving steps in, offering a level of precision that was once unimaginable. By harnessing the intense energy of a Nd:YAG laser beam, this technology vaporizes or removes material with pinpoint accuracy, leaving behind a precise and visually stunning mark. From delicate jewelry engravings to intricate industrial components, Nd:YAG laser engraving delivers unmatched precision and clarity, taking your projects to new heights.

The Advancements of Nd:YAG Laser Technology

Over the years, Nd:YAG laser technology has undergone significant advancements, pushing the boundaries of what’s possible in the world of engraving. From improvements in laser power and beam quality to enhanced control systems and software integration, these advancements have paved the way for more efficient, versatile, and high-quality engraving processes.

One notable advancement is the development of pulsed Nd:YAG lasers, which provide short bursts of high-energy laser pulses. This pulsed operation allows for precise control over the depth and intensity of the engraving, resulting in cleaner edges and finer details. Additionally, the integration of advanced cooling systems and ergonomic designs in modern Nd:YAG laser engraving machines ensures optimal performance and user-friendly operation.

In the following sections, we’ll delve deeper into the world of Nd:YAG laser engraving, exploring its applications across various industries, the factors to consider when choosing the right machine, essential techniques for successful engraving, and the exciting future trends that lie ahead.

Understanding Nd:YAG Laser Engraving

How Nd:YAG Laser Engraving Works: Exploring the Technology

Nd:YAG laser engraving is a sophisticated technique that harnesses the power of a neodymium-doped yttrium aluminum garnet (Nd:YAG) laser to achieve precise and intricate engravings on a variety of materials. The process involves the use of a high-energy laser beam that is focused onto the surface of the material to be engraved.

At the heart of Nd:YAG laser engraving is the Nd:YAG laser crystal. This crystal is doped with neodymium ions, which are responsible for generating the laser beam. When the laser is activated, the neodymium ions absorb energy from a flashlamp or diode laser, transitioning to an excited state.

As the neodymium ions return to their ground state, they release the absorbed energy in the form of photons. These photons bounce back and forth within the laser crystal, stimulating other excited neodymium ions to release more photons. This process is known as optical amplification and creates a powerful laser beam with a specific wavelength.

The laser beam is then directed towards a focusing lens, which narrows its diameter and increases its intensity. This concentrated beam of light is then directed onto the material to be engraved, where it interacts with the surface.

Key Components of Nd:YAG Laser Engraving Machines

Nd:YAG laser engraving machines consist of several key components that work together to deliver precise and efficient engraving results. These components include:

- Nd:YAG Laser Crystal: The neodymium-doped yttrium aluminum garnet crystal is the heart of the laser engraving machine. It is responsible for generating the laser beam used in the engraving process.

- Flashlamp or Diode Laser: This component provides the energy needed to excite the neodymium ions in the Nd:YAG crystal, triggering the laser emission.

- Resonator Cavity: The resonator cavity is a highly reflective chamber that contains the Nd:YAG crystal. It helps amplify the laser beam by reflecting photons back and forth, creating an intense and coherent laser beam.

- Focusing Lens: The focusing lens plays a crucial role in directing and concentrating the laser beam onto the material surface. It determines the spot size and focus depth, ultimately affecting the level of precision achieved in the engraving.

- Control System: The control system of the laser engraving machine allows for precise adjustment and control of laser parameters such as power, speed, and intensity. It ensures that the engraving process is carried out with accuracy and consistency.

Advantages of Nd:YAG Laser Engraving: Precision, Versatility, and Speed

Nd:YAG laser engraving offers a range of advantages that make it a preferred choice for various applications. These advantages include:

- Precision: Nd:YAG laser engraving delivers exceptional precision, allowing for the engraving of intricate designs and fine details. The focused laser beam can achieve high-resolution engravings with sharp edges and smooth finishes.

- Versatility: Nd:YAG laser engraving is compatible with a wide range of materials, including metals, plastics, ceramics, and more. It can handle diverse shapes, sizes, and textures, making it a versatile option for different industries and applications.

- Speed: Nd:YAG laser engraving machines can operate at high speeds, enabling efficient production processes. The laser beam quickly and precisely removes material, resulting in faster turnaround times and increased productivity.

Nd:YAG laser engraving is a technology that combines precision, versatility, and speed to deliver remarkable engraving results. By understanding the underlying principles of how Nd:YAG laser engraving works and familiarizing ourselves with the key components of the engraving machines, we gain a deeper appreciation for the power and potential of this technology. Whether you’re in the jewelry industry, manufacturing sector, or any other field that requires intricate and accurate engravings, Nd:YAG laser engraving can elevate your craftsmanship and productivity to new heights.

Applications of Nd:YAG Laser Engraving

Industrial Applications of Nd:YAG: Revolutionizing Manufacturing Processes

Nd:YAG laser engraving has revolutionized the manufacturing industry by offering unparalleled precision and versatility in various applications. One of the primary industrial uses of Nd:YAG laser engraving is in the production of high-quality and durable markings on metal components. The laser’s ability to create permanent, indelible marks on a wide range of metals, including stainless steel, aluminum, and titanium, makes it an invaluable tool in industries such as aerospace, automotive, and electronics.

The precision and speed of Nd:YAG laser engraving have also found applications in the fabrication of micro-components and microdevices. The ability to engrave intricate patterns and features on small-scale objects, such as microchips, sensors, and medical implants, enables the production of advanced technological devices with enhanced functionality.

Nd:YAG in Jewelry and Fashion: Intricate Designs with Laser Precision

In the world of jewelry and fashion, where intricate designs and exquisite details are paramount, Nd:YAG laser engraving has become a game-changer. Jewelry manufacturers and designers can now create intricate patterns, textures, and personalized engravings on various materials, including precious metals like gold and silver, as well as gemstones.

The laser’s precision allows for the creation of fine details, such as intricate filigree work and delicate patterns, that were once challenging to achieve by traditional hand engraving methods. With Nd:YAG laser engraving, jewelry artisans can bring their creative visions to life with remarkable precision and speed, giving their pieces a unique and distinctive edge in the market.

Personalization and Customization with Nd:YAG: Adding a Unique Touch

The demand for personalized and customized products has grown significantly in recent years, and Nd:YAG laser engraving plays a crucial role in meeting this demand. Whether it’s adding personalized messages, names, or monograms to items like gifts, promotional items, or even electronic devices, Nd:YAG laser engraving offers a convenient and efficient solution.

By harnessing the power of the laser beam, businesses can provide their customers with a truly unique and personalized experience. The versatility of Nd:YAG laser engraving allows for customization on various materials, including wood, glass, leather, and plastics. This opens up a world of possibilities for creating personalized items that cater to individual preferences and interests.

Nd:YAG Medical and Dental: Precision in Healthcare

Precision is of utmost importance in the medical and dental fields, where accuracy and reliability can make a significant difference in patient outcomes. Nd:YAG laser engraving has found its place in these industries, offering precise and consistent markings on surgical instruments, implants, and medical devices.

In dentistry, Nd:YAG laser engraving is used to create permanent markings on dental implants, crowns, and other dental prosthetics. These markings assist in precise placement and alignment during dental procedures, ensuring optimal results for patients.

Additionally, Nd:YAG laser engraving is utilized in the medical device manufacturing industry to create unique identification numbers, logos, and safety information on various medical devices and equipment. The high precision and durability of laser engravings ensure that vital information remains intact, even after repeated sterilization and use.

The applications of Nd:YAG laser engraving span across various industries, showcasing its versatility and precision. From revolutionizing manufacturing processes in industrial settings to enabling intricate designs in jewelry and fashion, as well as adding a unique touch through personalization and customization, and ensuring precision in healthcare, Nd:YAG laser engraving continues to push boundaries and redefine what is possible in the world of precision engraving.

Choosing the best Nd:YAG Laser Engraving Machine

When it comes to selecting an Nd:YAG laser engraving machine, there are several important factors to consider. Choosing the right machine can significantly impact the quality of your engravings, the efficiency of your workflow, and ultimately, the success of your projects. Let’s explore some key factors to keep in mind when selecting an Nd:YAG laser engraver.

Factors to Consider When Selecting an Nd:YAG Laser Engraver

Nd:YAG Power and Wattage: Finding the Perfect Balance

One of the first considerations when choosing an Nd:YAG laser engraving machine is the power and wattage. The power of the laser determines its cutting and engraving capabilities. Higher power lasers can engrave deeper and cut through thicker materials, while lower power lasers are more suitable for delicate engravings on softer materials.

It’s important to find the perfect balance of power and wattage that aligns with your specific needs. Consider the types of materials you’ll be working with and the level of intricacy required for your engravings. A machine with adjustable power settings can provide versatility, allowing you to adapt to different projects and materials.

Nd:YAG Engraving Area and Size: Matching Your Project Requirements

The engraving area and size of the machine are crucial factors to consider. The size of the machine determines the maximum dimensions of the objects you can engrave. If you primarily work with small items, a compact machine with a smaller engraving area may suffice. However, if you plan to work on larger projects or need the flexibility to engrave a variety of sizes, a machine with a larger engraving area would be more suitable.

Evaluate your typical project requirements and ensure that the machine’s engraving area can accommodate them. It’s also worth considering the accessibility and ease of loading and unloading materials within the machine to ensure smooth workflow and efficiency.

Nd:YAG Software Compatibility: Enhancing Workflow Efficiency

The compatibility of the Nd:YAG laser engraving machine with design software is an essential aspect to consider. Look for machines that are compatible with industry-standard design software, such as Adobe Illustrator or CorelDRAW. This compatibility allows for seamless integration between your design files and the machine, streamlining the workflow and reducing the chances of errors or design discrepancies.

Furthermore, consider if the machine offers advanced features like raster and vector engraving capabilities. These features enable you to achieve precise and detailed engravings, replicating your designs with accuracy.

Additionally, check if the machine supports file formats commonly used in the industry, such as SVG, DXF, or AI. Compatibility with a wide range of file formats ensures that you can easily import and engrave designs from different sources, enhancing your creative possibilities.

The best Nd:YAG laser engraving machine requires careful consideration of factors such as power and wattage, engraving area and size, and software compatibility. By assessing your specific needs and aligning them with the capabilities of the machine, you can make an informed decision that sets the foundation for successful engraving projects. Remember, investing in a high-quality and suitable Nd:YAG laser engraver is an investment in the precision and efficiency of your work, ultimately contributing to the overall success of your endeavors.

Techniques and Tips for Successful Nd:YAG Laser Engraving

Achieving remarkable results with Nd:YAG laser engraving requires not only a high-quality machine but also a thorough understanding of the techniques and tips that can enhance your precision and efficiency. In this section, we will explore some essential techniques and tips to help you achieve successful Nd:YAG laser engravings.

Nd:YAG Adjusting Laser Settings: Optimizing Precision and Quality

Fine-tuning the laser settings is crucial for achieving optimal precision and quality in your engravings. Key parameters to consider include laser power, pulse duration, repetition rate, and spot size. These settings can be adjusted based on the material you’re engraving, the desired depth or darkness of the engraving, and the speed at which you’re operating.

By finding the right balance of laser settings, you can achieve clean and crisp engravings without compromising on the material’s integrity. Experimenting with different settings on sample pieces can help you understand how each parameter affects the outcome and fine-tune the settings for your specific needs.

Nd:YAG Exploring Engraving Modes: Line, Fill, and Contour

Nd:YAG laser engraving machines offer various engraving modes, each suited for different applications and effects. The three primary engraving modes are line engraving, fill engraving, and contour engraving.

Line engraving involves creating precise, single lines for detailed designs or text. Fill engraving, on the other hand, involves engraving larger areas by systematically filling them with patterns or textures. Contour engraving creates engraved lines that follow the contours of the design, enhancing its three-dimensional appearance.

Understanding the capabilities and applications of each engraving mode allows you to choose the most suitable one for your project, ensuring desired results with efficiency.

Nd:YAG Design Considerations for Laser Engraving

When creating designs for Nd:YAG laser engraving, there are certain considerations to keep in mind. First, ensure that the design is in a vector format, such as SVG or AI, to maintain scalability and avoid pixelation. Vector graphics allow the laser to precisely follow the design’s paths, resulting in sharp and accurate engravings.

Additionally, consider the size and complexity of the design. Smaller designs with intricate details may require slower engraving speeds to ensure precision. Experimenting with different speeds and observing the results can help you determine the optimal settings for your specific design.

Moreover, explore the use of grayscale or halftone techniques to add depth and shading to your engravings. These techniques can create stunning visual effects, especially when working with photographs or intricate artwork.

Nd:YAG Cleaning and Maintenance: Ensuring Longevity and Performance

Regular cleaning and maintenance are vital to ensure the longevity and optimal performance of your Nd:YAG laser engraving machine. Dust and debris can accumulate on the lens, affecting the quality of engravings. It’s essential to clean the lens and other critical components regularly using appropriate cleaning tools and techniques recommended by the manufacturer.

Additionally, check for any signs of wear or damage on the laser components, such as the flashlamp or the crystal. Promptly addressing any issues and scheduling routine maintenance can help prevent major problems and ensure consistent performance.

Furthermore, ensure that the machine is placed in a clean and well-ventilated environment to minimize the risk of contamination and overheating.

Mastering the techniques and tips for successful Nd:YAG laser engraving can elevate the quality and precision of your engravings. By adjusting laser settings, exploring engraving modes, considering design factors, and maintaining your machine diligently, you can achieve remarkable results with efficiency and consistency. With practice and a keen eye for detail, you’ll unlock the full potential of Nd:YAG laser engraving and bring your creative visions to life with unparalleled precision.

Innovations and Future Trends in Nd:YAG Laser Engraving

As technology continues to evolve, Nd:YAG laser engraving is no exception. Innovations in Nd:YAG laser technology are constantly pushing the boundaries of what is possible, while new trends are shaping the future of this engraving technique. In this section, we will explore some of the exciting advancements and emerging trends in Nd:YAG laser engraving.

Advancements in Nd:YAG Laser Technology: Pushing Boundaries

Nd:YAG laser technology has witnessed significant advancements over the years, enabling engravers to achieve higher levels of precision, speed, and versatility. One notable advancement is the development of more efficient laser systems, allowing for improved energy conversion and reduced heat generation. This results in enhanced engraving quality and reduced material damage.

Another exciting development is the integration of advanced control systems and software algorithms, which enable real-time monitoring and adjustments of laser parameters. This ensures greater accuracy and consistency throughout the engraving process, even when working with complex designs or challenging materials.

Furthermore, advancements in beam delivery systems have led to improved beam quality, allowing for finer details and sharper edges in engravings. These innovations contribute to the overall performance and efficiency of Nd:YAG laser engraving machines.

Nd:YAG Automation and Robotics: Streamlining Engraving Workflows

Automation and robotics are revolutionizing various industries, and Nd:YAG laser engraving is no exception. The integration of automation technologies with Nd:YAG laser engraving machines is streamlining engraving workflows and enhancing productivity.

Automated systems can handle the loading and unloading of materials, reducing the need for manual intervention and minimizing downtime. This not only improves efficiency but also ensures consistent positioning of materials, resulting in precise and accurate engravings.

Additionally, robotic arms can be programmed to perform complex engraving tasks, allowing for increased flexibility and faster production. The ability to program specific patterns and paths enables intricate designs to be executed with ease and speed.

The combination of automation and robotics with Nd:YAG laser engraving machines is empowering engravers to take on larger projects, meet tight deadlines, and maintain consistent quality, ultimately driving the industry forward.

Nd:YAG Lasers in Emerging Industries: Exploring New Frontiers

Nd:YAG lasers are finding applications in emerging industries, expanding the horizons of laser engraving. One such industry is the renewable energy sector, where Nd:YAG lasers are used for precision marking and engraving on solar panels, batteries, and other energy storage devices. These lasers provide the accuracy and durability required for long-lasting identification and traceability in this growing field.

Moreover, Nd:YAG laser engraving is making significant strides in the field of medical devices and implants. The ability of Nd:YAG lasers to engrave on a variety of materials, including metals and polymers, makes them ideal for creating intricate designs and precise markings on medical instruments and implants. This ensures proper identification, tracking, and safety in the healthcare industry.

Furthermore, emerging industries such as aerospace, defense, and automotive are also leveraging the power of Nd:YAG laser engraving for applications such as part marking, serial numbering, and branding.

The future of Nd:YAG laser engraving holds immense potential as new industries continue to discover its capabilities and innovative applications.

The field of Nd:YAG laser engraving is constantly evolving, driven by advancements in laser technology and the integration of automation and robotics. These innovations are pushing the boundaries of precision and efficiency, while opening up new frontiers in emerging industries. As the industry continues to grow, the possibilities for Nd:YAG laser engraving are expanding, promising a future filled with even greater potential and opportunities.

Nd:YAG Case Studies: Success Stories and Inspirational Examples

When it comes to Nd:YAG laser engraving, there are numerous success stories and inspirational examples that showcase the remarkable capabilities of this precision technology. In this section, we will delve into some notable case studies that highlight the exceptional results achieved through Nd:YAG laser engraving. These stories of artistic achievement celebrate the fusion of precision and creativity, demonstrating the immense potential of this engraving technique.

Showcasing Remarkable Nd:YAG Laser Engraving Projects

One fascinating case study involves the collaboration between a renowned artist and a team of skilled engravers. The artist, known for pushing the boundaries of creativity, wanted to incorporate intricate engravings into their sculptures, showcasing a seamless fusion of artistry and precision. The Nd:YAG laser engraving technology proved to be the perfect tool to transform their vision into reality.

The artist provided their designs, which were meticulously engraved onto various materials, including metals and glass. The precision and versatility of the Nd:YAG laser engraving machine allowed for the realization of intricate details and complex patterns that would have been extremely challenging to achieve using traditional engraving methods.

The resulting sculptures were a testament to the power of Nd:YAG laser engraving, captivating viewers with their breathtaking beauty and flawless execution. This case study serves as an inspiration to artists and designers, showcasing the transformative potential of Nd:YAG laser technology in the realm of artistic expression.

Stories of Artistic Achievement of Nd:YAG: Celebrating Precision and Creativity

In another remarkable case study, a jewelry designer sought to push the boundaries of traditional jewelry engraving techniques. They aimed to create unique pieces that would not only capture the attention of discerning customers but also demonstrate the intricacy and precision achievable through Nd:YAG laser engraving.

With the help of expert engravers and state-of-the-art Nd:YAG laser engraving machines, the jewelry designer embarked on a journey of artistic exploration. The laser technology allowed for the creation of finely detailed patterns, intricate motifs, and personalized engravings on a variety of precious metals and gemstones.

The resulting jewelry pieces were nothing short of awe-inspiring. Each piece was a testament to the designer’s creativity and the precision of Nd:YAG laser engraving. From delicate filigree designs to elaborate engravings on gemstone surfaces, the jewelry pieces became wearable works of art, captivating customers with their exquisite beauty and attention to detail.

These success stories not only showcase the immense potential of Nd:YAG laser engraving in the world of art and design but also inspire aspiring artists and engravers to explore the limitless possibilities offered by this precision technology.

The case studies presented in this section shed light on the remarkable achievements and inspirational examples of Nd:YAG laser engraving. From collaborations with artists to groundbreaking jewelry designs, these stories celebrate the fusion of precision and creativity that this technology enables. Nd:YAG laser engraving continues to push the boundaries of artistic expression and opens up new avenues for innovation and excellence in various industries. As we witness these success stories, we are reminded of the transformative power of Nd:YAG laser engraving, inspiring us to unlock our own creative potential and embrace the limitless possibilities it offers.

The Impact of Nd:YAG Laser Engraving

In today’s modern manufacturing landscape, Nd:YAG laser engraving has emerged as a game-changer, revolutionizing the way products are crafted and adding a new dimension of precision and versatility to the manufacturing process. This section explores the significant impact of Nd:YAG laser engraving in various industries and how it has become a driving force for innovation.

The Role of Nd:YAG Laser Engraving in Modern Manufacturing

Nd:YAG laser engraving has transformed the manufacturing industry by offering unparalleled precision and efficiency in the production of intricate and detailed components. This cutting-edge technology has found its application in diverse sectors such as automotive, aerospace, electronics, and more.

By harnessing the power of focused laser beams, Nd:YAG laser engraving machines can etch precise markings, intricate designs, and micro-sized features onto a wide range of materials. From metal components to ceramics and plastics, the versatility of Nd:YAG laser engraving ensures that manufacturers can achieve the desired level of precision and aesthetic appeal in their products.

Precision as a Competitive Advantage

In today’s highly competitive market, precision is a key differentiator that sets manufacturers apart from their competitors. Nd:YAG laser engraving provides an unparalleled level of accuracy and repeatability, allowing manufacturers to deliver products with exceptional quality and craftsmanship.

The precision offered by Nd:YAG laser engraving opens up new possibilities for product design, enabling the creation of complex and intricate patterns, textures, and engravings. This level of detail not only enhances the aesthetic appeal of products but also adds value by communicating brand identity, personalization, and exclusivity.

Furthermore, the precise and controlled nature of Nd:YAG laser engraving minimizes the risk of errors and reduces material waste, optimizing production processes and ensuring cost-effectiveness for manufacturers.

Driving Innovation with Nd:YAG Laser Engraving

Nd:YAG laser engraving is a catalyst for innovation in various industries. By enabling manufacturers to achieve intricate designs and precise markings that were previously unattainable, this technology paves the way for new possibilities and breakthroughs.

In the automotive industry, for example, Nd:YAG laser engraving is used to create precise serial numbers, identification codes, and logos on engine parts, ensuring traceability and authenticity. In the electronics sector, Nd:YAG laser engraving allows for the fabrication of intricate circuit boards with precision etchings, enhancing the performance and reliability of electronic devices.

Moreover, Nd:YAG laser engraving plays a vital role in the creation of medical devices, enabling the production of precise surgical instruments, implants, and intricate components for diagnostic equipment. The exceptional precision and control offered by this technology contribute to advancements in medical treatments and procedures.

In conclusion, Nd:YAG laser engraving has had a profound impact on modern manufacturing. Its role in delivering precision, enhancing competitiveness, and driving innovation cannot be overstated. As manufacturers continue to embrace this cutting-edge technology, we can expect to see further advancements in product design, quality, and efficiency. Nd:YAG laser engraving is a testament to the power of technological innovation, pushing the boundaries of what is possible and shaping the future of manufacturing.

Addressing Common Challenges in Nd:YAG Laser Engraving

Nd:YAG laser engraving is a powerful technology that offers exceptional precision and versatility in various industries. However, like any manufacturing process, it comes with its own set of challenges. In this section, we will delve into some common challenges faced in Nd:YAG laser engraving and explore effective strategies to address them.

Nd:YAG Overcoming Material Limitations

One of the primary challenges in Nd:YAG laser engraving is dealing with different types of materials. While Nd:YAG lasers are known for their ability to engrave metals effectively, engraving non-metallic materials such as plastics, ceramics, and composites can be more challenging.

To overcome this challenge, it is crucial to understand the properties of the materials being engraved. Adjusting laser settings, such as pulse duration, frequency, and power, can optimize the engraving process for specific materials. Additionally, using appropriate techniques like pre-treatment, masking, or employing different laser parameters can help achieve desired results on challenging materials.

Nd:YAG Managing Workflow Efficiency and Productivity

Efficient workflow management is key to maximizing productivity in Nd:YAG laser engraving. Ensuring smooth transitions between different engraving jobs, minimizing downtime, and optimizing the use of resources are essential for maintaining high productivity levels.

One strategy is to implement batch processing, grouping similar engraving tasks together to minimize setup and changeover time. This approach streamlines the workflow, allowing for faster and more efficient processing of multiple items.

Investing in advanced software solutions that enable job scheduling, material optimization, and real-time monitoring can also significantly enhance workflow efficiency. These tools provide insights into machine utilization, engraving progress, and maintenance schedules, enabling operators to make informed decisions and optimize productivity.

Nd:YAG Troubleshooting and Maintenance Tips

As with any complex machinery, Nd:YAG laser engraving machines require regular maintenance and occasional troubleshooting to ensure optimal performance. Some common issues that may arise include beam misalignment, power fluctuations, or degraded engraving quality.

Regular cleaning and inspection of optical components, such as lenses and mirrors, help prevent dirt or debris buildup that can affect laser performance. Calibration of the laser beam, ensuring proper alignment and focus, is also crucial for maintaining consistent engraving quality.

In case of troubleshooting, referring to the manufacturer’s guidelines and seeking expert assistance can help identify and resolve issues efficiently. Regular maintenance, including the replacement of consumables like flashlamps and cooling fluids, should be performed as recommended by the manufacturer to ensure reliable and consistent engraving results.

While Nd:YAG laser engraving offers exceptional precision and versatility, addressing common challenges is essential for achieving optimal results. By understanding material limitations, implementing efficient workflow management strategies, and following proper troubleshooting and maintenance practices, manufacturers can overcome obstacles and harness the full potential of Nd:YAG laser engraving. With careful attention to these aspects, businesses can ensure consistent and high-quality engraving, enhancing their competitive edge in the market.

Conclusion

In this fast-paced era of technological advancements, embracing the precision powerhouse of Nd:YAG laser engraving opens up a world of possibilities. From industrial applications to jewelry design and medical advancements, the versatility of this technology has revolutionized numerous industries.

The unrivaled precision offered by Nd:YAG laser engraving machines is a game-changer. With the ability to etch intricate designs on various materials, these machines have become indispensable tools for manufacturers, artisans, and healthcare professionals.

The advantages of Nd:YAG laser engraving are multifaceted. Its ability to deliver precise and intricate engravings with exceptional quality sets it apart from traditional engraving methods. The versatility to work on diverse materials, including metals, plastics, ceramics, and composites, makes it a go-to choice across different industries.

With Nd:YAG laser engraving, customization and personalization reach new heights. The technology enables individuals and businesses to add a unique touch to their products, creating a lasting impression on customers. From personalized gifts to branding elements, the precision and attention to detail achieved through Nd:YAG laser engraving leave a remarkable impact.

Moreover, the future of Nd:YAG laser engraving looks promising, with ongoing advancements pushing the boundaries of what is possible. The integration of automation and robotics streamlines workflows, enhancing efficiency and productivity. As emerging industries embrace the power of Nd:YAG laser engraving, new frontiers are explored, creating innovative applications in fields yet to be fully realized.

In conclusion, Nd:YAG laser engraving has emerged as a precision powerhouse with a wide range of applications. Its impact on modern manufacturing, healthcare, and personalization is undeniable. By harnessing the unparalleled precision of Nd:YAG laser engraving, individuals and businesses can unlock new possibilities and set themselves apart in a competitive landscape.

Embrace the precision powerhouse of Nd:YAG laser engraving and witness the transformative power it holds. Let your imagination soar as you explore the limitless potential of this technology, pushing boundaries, and achieving unparalleled precision in your endeavors. The future is bright, and with Nd:YAG laser engraving, you have the key to unlock it.